Project

Technology

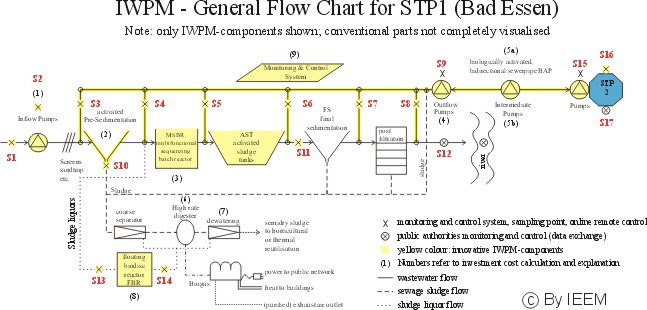

The innovation of the Project would be a functional link between selected sewage treatment plants (STP) to realise IWPM - Integrated Wastewater Purification Management. IWPM means that hydraulic flows and contaminants (especially nutrients) are equalised and distributed to an optimum between different STPs, depending on their capacities at any given time. Besides this innovation of an IWPM-system, the innovations of the IWPM-components have to be considered (BAP, MSBR, FBR -> see Figure 1).

PCC - pipe connection and control system

including a 16.5 km pressurised 2 x 300 mm twin pipe with 3 bi-directional pumping stations (pipe equipment working with wastewater as well as with liquid sludge), operated as biologically activated pipe reactor with ca. 1,000 m³ [the wastewater in the pipe is enriched with activated sewage sludge to drive the biological hydrolisation (for phosphorus removal) and denitrification for N-removal]. Included is an on-line monitoring and remote control system to steer pumps, valves, aerators etc. for optimum IWPM.

MWP - modified wastewater purification

including activated pre-sedimentation (sludge settlement and sludge pumping controlled to best hydrolisis effect) and the multifunctional sequencing batch reactor MSBR. [MSBR will be operated with great flexibility, according to different inflow situations: (a) As conventional SBR, in parallel to AST + FS (inflow diverted between SBR and AST; outflow SBR goes to post-filtration); (b) As aerated tank (inflow shared with AST, outflow to final sedimentation); (c) In-line, as first biological stage; (d) As equalising tank, biological function less than maximum, but storage of nutrients provided.]

EST - enhanced sludge treatment